Murphy’s Law Strikes Every Business (The Universal Problem)

“On the eighth day, God said, ‘O.K. Murphy, you take over!'”

We all recognize the bitter humor in Murphy’s Law. Who hasn’t been a victim of its seemingly personal vendetta against our success? The most common variations haunt business owners everywhere: “If anything can go wrong, it will,” “Left to themselves, things tend to go from bad to worse,” and “Everything goes wrong all at once.”

These moments feel personal, as if the universe conspires against your success precisely when stakes are highest. Murphy’s Law seems to possess an uncanny ability to strike during the most critical moments, when you can least afford operational failures.

The psychological impact extends beyond immediate frustration. As legendary UCLA basketball coach John Wooden once observed, “If you don’t have time to do it right, when will you have time to do it over?” When everything goes wrong simultaneously, business owners experience a sense of helplessness that can paralyze decision-making. The randomness feels overwhelming, creating a reactive mindset that focuses on firefighting rather than prevention.

But what if Murphy’s Law isn’t as random as it appears? What if most of these “inevitable” failures stem from systematic weaknesses rather than cosmic conspiracy? What if there’s a proven way to minimize Murphy’s impact on your business operations?

What’s in this article:

The Hidden Cost of Murphy’s Mayhem

Why Traditional Problem-Solving Fails

The SYSTEMology Antidote

Building Murphy-Proof Business Operations

Real-World Examples

The Systematic Approach

Advanced Murphy-Proofing Strategies

The ROI of Murphy-Proof Operations

Your Action Plan

Frequently Asked Questions

Conclusion: From Victim to Master of Your Destiny

The Hidden Cost of Murphy’s Mayhem in Your Business

Research reveals that borrowing from the Pareto Principle, approximately 20% of business problems represent truly random occurrences beyond your control. However, 80% of what business owners attribute to Murphy’s Law actually stems from systematic failures within their control. These preventable problems compound, creating cascading failures that feel like cosmic persecution but actually represent operational shortcomings.

The financial impact often remains hidden because business owners accept operational chaos as “normal.” Mistakes, rework, delays, and customer dissatisfaction get categorized as “part of doing business” rather than systematic failures requiring prevention. The true cost includes direct expenses from errors, opportunity costs from missed initiatives, customer lifetime value lost through poor experiences, and employee productivity decreased by operational stress.

Consider the compound effect of systematic failures. A documentation problem leads to training inconsistencies. Training inconsistencies create quality variations. Quality variations generate customer complaints. Customer complaints require management attention. Management distraction prevents strategic work. Strategic delays enable competitor advantages. Each failure creates conditions for additional failures, amplifying Murphy’s apparent influence.

“How many strategic partnerships never develop because leadership remains trapped firefighting operational problems?”

Most devastating are the invisible opportunity costs. How many strategic partnerships never develop because leadership remains trapped firefighting operational problems? How many innovative product ideas never get explored because there’s no capacity for strategic thinking? How many growth opportunities pass unnoticed because daily crises consume all available attention?

Why Traditional Problem-Solving Fails Against Murphy

The Hero Complex Trap

Business owners often become exceptionally skilled at solving problems, earning them recognition as the “knight in shining armor” who saves the day when crises emerge. This problem-solving prowess becomes addictive, creating unconscious patterns that actually increase Murphy’s influence over time.

The hero complex trap works like this: when problems arise, business owners step in with quick solutions that resolve immediate issues. Teams learn to depend on this heroic intervention rather than developing systematic problem-prevention capabilities. The business owner’s problem-solving skills improve through constant practice, while team members become increasingly dependent.

Michael Gerber identified the core issue in The E-Myth: “The problem with being indispensable is that you can’t grow beyond yourself.” This creates a horrible cycle that’s almost impossible to break. The more problems the business owner solves, the better they become at problem-solving. The better they become at problem-solving, the more their team depends on them. The more their team depends on them, the more problems require their personal attention. Instead of building organizational problem-prevention capabilities, they build organizational dependency.

The systematic solution involves shifting from reactive problem-solving to proactive problem-prevention. Instead of becoming better at fixing problems, successful business owners become better at creating systems that prevent problems from occurring initially.

“Instead of becoming better at fixing problems, successful business owners become better at creating systems that prevent problems from occurring initially.”

The Illusion of Random Events

Murphy’s Law feels personal because individual incidents appear random and unpredictable. However, systematic analysis reveals that most operational failures follow predictable patterns rooted in systematic weaknesses rather than cosmic conspiracy.

Only approximately 20% of business problems represent truly random occurrences that no reasonable systematic approach could prevent. Equipment failures due to manufacturing defects, natural disasters, or sudden market disruptions fall into this category. These represent the cost of doing business in an imperfect world.

The remaining 80% of problems stem from systematic failures in six basic areas: human factors, process design, policy clarity, equipment maintenance, materials quality, and environmental controls. Each category offers systematic improvement opportunities that dramatically reduce Murphy’s apparent influence.

Human factors include insufficient training, unclear expectations, inadequate communication, and knowledge gaps. Process design encompasses workflow inefficiencies, missing safeguards, inadequate quality controls, and poor documentation. Policy clarity involves ambiguous procedures, conflicting guidelines, and inconsistent enforcement.

Equipment maintenance covers preventive maintenance schedules, monitoring systems, replacement planning, and operator training. Materials quality includes supplier relationships, inspection procedures, inventory management, and quality standards. Environmental controls encompass workspace design, safety measures, regulatory compliance, and emergency procedures.

The Pareto Principle applies directly to operational problems: 20% of systematic improvements typically eliminate 80% of recurring problems. This mathematical relationship explains why systematic approaches prove so effective against Murphy’s Law while traditional firefighting approaches fail.

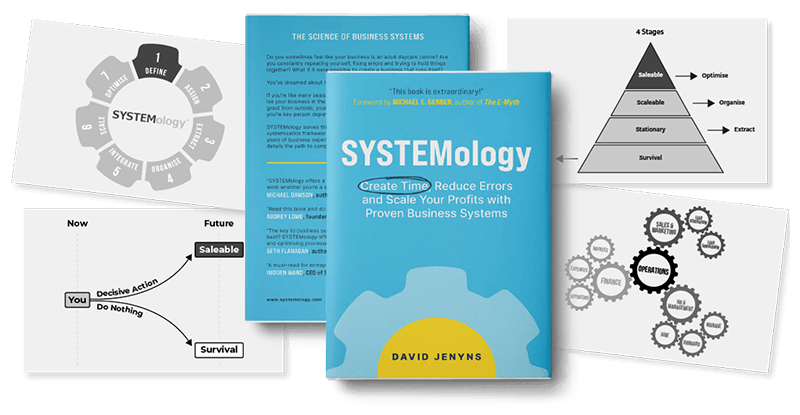

The SYSTEMology Antidote to Murphy’s Law

Systems Thinking vs. Murphy Thinking

Quality management pioneer W. Edwards Deming had a saying that revolutionized manufacturing: “Every system is perfectly designed to get the results it gets.” This principle transforms how we view operational failures. Instead of seeing them as random Murphy incidents, systematic thinking reveals that poor results stem from systematic design flaws.

Systematic thinking fundamentally changes how organizations handle challenges. Instead of viewing problems as random events requiring heroic intervention, systematic thinkers examine underlying causes and implement prevention-focused solutions.

Murphy thinking focuses on individual incidents, personal blame, and reactive responses. When equipment fails, it asks “Who was responsible?” and “How quickly can we fix it?” This approach treats symptoms while ignoring systematic causes that virtually guarantee similar failures in the future.

The Law of Cause and Effect defeats Murphy’s Law by revealing that apparent randomness usually stems from systematic patterns. Every effect has identifiable causes. Every problem provides learning opportunities for systematic improvement. Every failure reveals prevention opportunities for future enhancement.

Your business operates as a collection of interconnected systems, similar to the human body. When systematic thinking becomes organizational habit, problems transform from overwhelming crises into improvement opportunities. Teams develop capabilities for identifying patterns, analyzing causes, and implementing systematic solutions.

“Your business operates as a collection of interconnected systems, similar to the human body.”

The shift from Murphy thinking to systems thinking requires cultural transformation. Teams must learn to see beyond individual incidents to understand systematic relationships. They need training in root cause analysis, prevention-focused thinking, and collaborative problem-solving approaches.

The Six Root Causes Framework

Every business problem ultimately stems from weaknesses in one of six systematic areas: human factors, process design, policy clarity, equipment maintenance, materials quality, or environmental controls. This framework provides systematic approaches to Murphy-proofing operations.

Human factors encompass training systems, communication procedures, knowledge transfer methods, and performance management approaches. Systematic improvements might include comprehensive onboarding programs, regular skills development, clear job descriptions, and effective feedback mechanisms.

Process design covers workflow optimization, quality controls, documentation standards, and continuous improvement methods. Systematic enhancements could involve streamlined procedures, built-in safeguards, visual process maps, and regular process reviews.

Policy clarity involves establishing clear expectations, consistent procedures, effective communication, and appropriate accountability measures. Systematic improvements might include policy documentation, regular training updates, clear escalation procedures, and performance metrics.

Equipment maintenance encompasses preventive maintenance schedules, monitoring systems, operator training, and replacement planning. Systematic approaches could involve maintenance checklists, performance tracking, operator certification, and proactive replacement strategies.

Materials quality includes supplier relationships, inspection procedures, inventory management, and quality standards. Systematic improvements might involve supplier audits, incoming inspection protocols, inventory optimization, and quality metrics.

Environmental controls cover workspace design, safety measures, regulatory compliance, and emergency procedures. Systematic enhancements could include ergonomic improvements, safety training programs, compliance monitoring, and emergency response planning.

Building Murphy-Proof Business Operations

Critical Client Flow (CCF) as Foundation

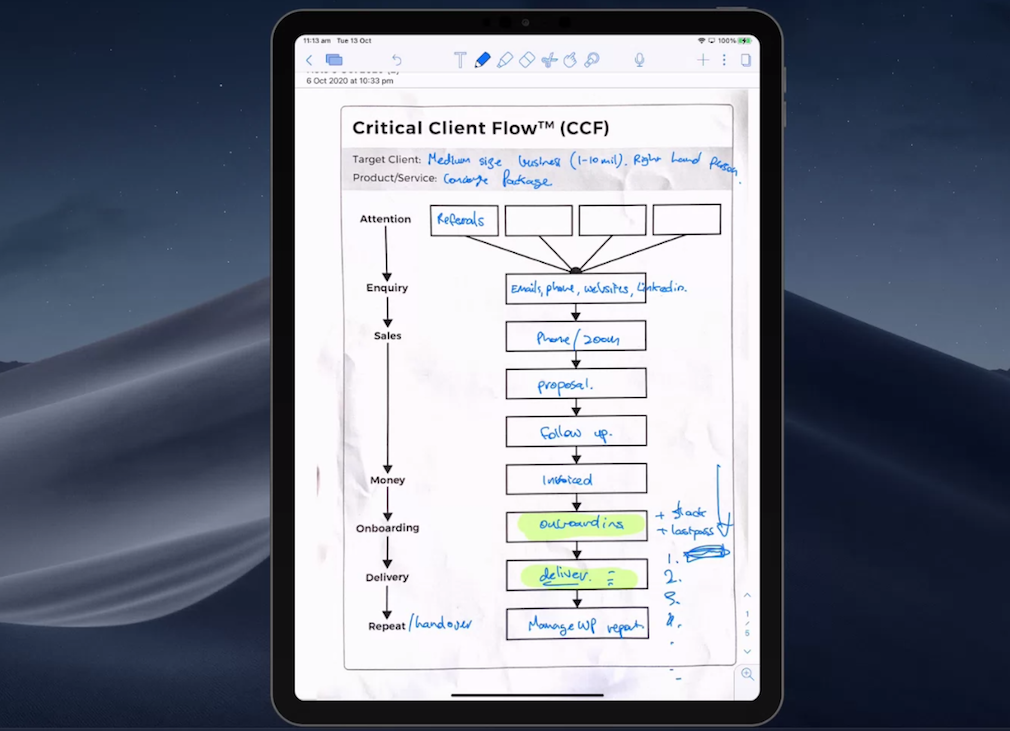

Your Critical Client Flow represents the foundation for Murphy-proofing business operations by mapping exactly where operational failures typically impact customer experiences. This systematic exercise reveals vulnerability points while creating opportunities for targeted prevention efforts.

The CCF documents how one specific client type experiences your complete service delivery process for one primary product or service. This focused approach forces clarity about your core value proposition while revealing every point where Murphy might strike during customer interactions.

Start by identifying your primary target client and most important product or service offering. Map every step from initial awareness through final delivery and follow-up, including all touchpoints, decision points, handoffs between departments, and potential failure modes.

Document not just what should happen but also what typically goes wrong at each stage. Where do delays usually occur? What mistakes happen repeatedly? Which steps create customer confusion or dissatisfaction? This systematic analysis reveals Murphy’s favorite hunting grounds within your operations.

Test your completed CCF by sharing it with someone outside your business who understands roughly what you do but isn’t directly involved. If they can understand your process without detailed explanation, you’ve achieved appropriate clarity for systematic improvement efforts.

Your CCF becomes the foundation for identifying supporting systems throughout your organization. Each step typically requires underlying processes for effective execution, providing natural prioritization for subsequent Murphy-proofing initiatives.

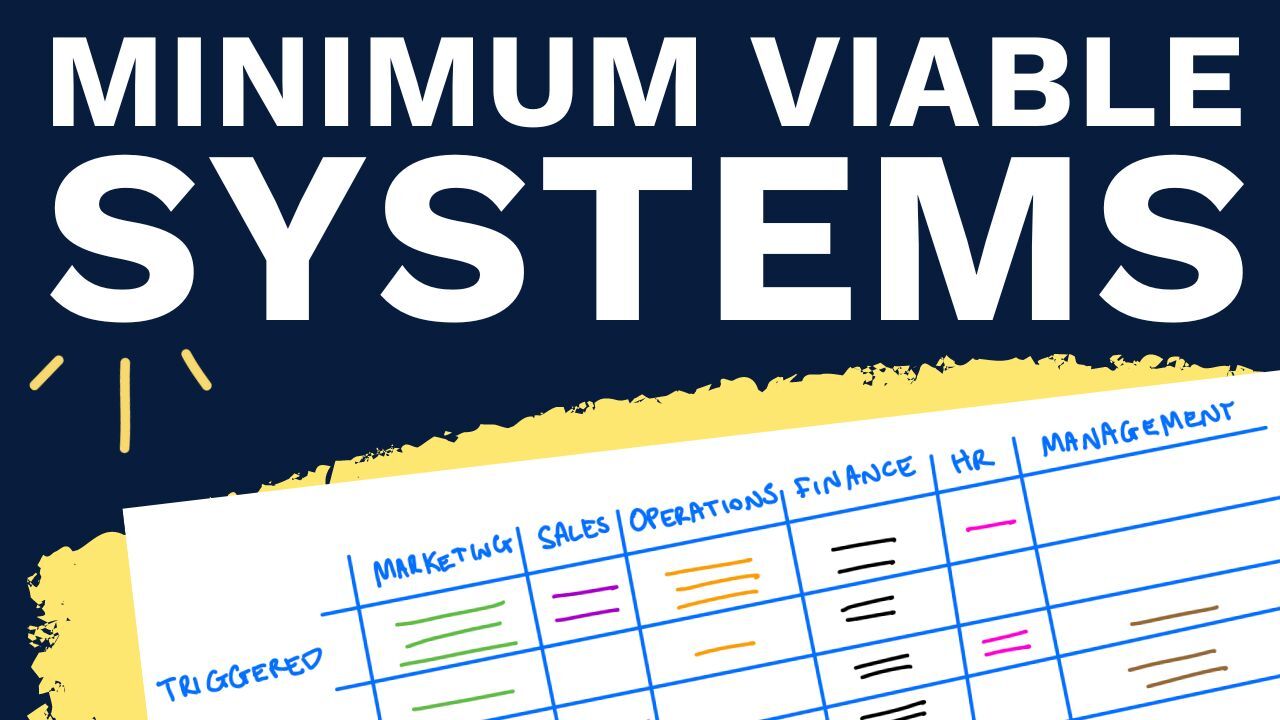

Minimum Viable Systems (MVS) for Problem Prevention

Rather than attempting to systematize everything simultaneously, the Minimum Viable Systems approach focuses on the 7-10 critical processes per department that prevent 80% of Murphy’s mischief when properly documented and implemented.

Think about your business like the human body. Your respiratory system needs your circulatory system to distribute oxygen. Your digestive system relies on your endocrine system to regulate metabolism. If any vital system fails, consequences can be severe throughout the entire organism.

Your business operates identically. Marketing systems depend on sales systems for lead conversion. Operations systems require finance systems for resource allocation. Human resources systems enable all other systems through team development. Each system depends on others for optimal performance.

The MVS approach identifies which systems most directly impact customer experience, revenue generation, and operational efficiency. Sales departments might prioritize lead qualification, proposal development, and client onboarding systems. Operations could focus on quality control, delivery coordination, and customer communication processes.

“The MVS approach creates momentum through early wins while building systematic capabilities throughout your organization.”

Each department typically has core systems that drive most operational results while preventing most Murphy incidents. Rather than documenting hundreds of procedures, focus on the critical few that eliminate the majority of recurring problems.

Quality control systems might include inspection checklists, review procedures, customer feedback mechanisms, and performance standards. Training systems could encompass onboarding programs, skills development, knowledge transfer, and performance evaluation procedures.

Backup and contingency systems provide insurance against Murphy’s inevitable attempts at disruption. These might include data backup procedures, emergency contact lists, supplier alternatives, and crisis communication protocols.

The MVS approach creates momentum through early wins while building systematic capabilities throughout your organization. As teams experience the benefits of Murphy-proof operations in critical areas, they develop enthusiasm for expanding systematic approaches to additional processes.

Error-Proofing Techniques (Poka-Yoke)

Japanese manufacturing developed error-proofing techniques called “poka-yoke” that make mistakes impossible or immediately obvious when they occur. These systematic approaches provide powerful tools for Murphy-proofing business operations.

Prevention-based error-proofing designs processes that make mistakes physically impossible. Software interfaces that disable “submit” buttons until required fields are completed represent prevention-based approaches. Accounting procedures that require dual authorization for significant expenditures prevent accidental overspending.

Detection-based error-proofing creates immediate feedback when mistakes occur, enabling rapid correction before problems compound. Automated spell-checking in documents provides detection-based error-proofing. Quality control inspections at critical process points detect problems before they reach customers.

Checklists represent simple but powerful error-proofing tools. Aviation industry safety depends heavily on systematic checklist usage that prevents potentially catastrophic oversights. Medical procedures employ checklists that dramatically reduce surgical errors and complications.

Effective business checklists include all critical steps, use clear language, specify completion criteria, and require verification signatures. They should be easily accessible, regularly updated, and consistently used by all team members performing related tasks.

Automated safeguards leverage technology to prevent common errors. Customer relationship management systems can automatically flag duplicate entries. Inventory management systems can prevent overselling products. Financial systems can require approval workflows for significant transactions.

Real-World Examples: Businesses That Defeated Murphy

Case Study 1: Oh Crap Poo Bags Transformation

Oh Crap Poo Bags felt the full impact of Murphy’s Law during their rapid growth phase. Sales skyrocketed from 200,000 to 6.3 million units within just a few years, but their operational systems struggled to keep pace.

The chaos was visible everywhere: floor-to-ceiling stacks of boxes filling residential spaces, advertising campaigns they had to shut down because they couldn’t fulfill orders, and Bruce’s vacation that brought the entire business to a complete halt while wages continued.

When they brought on full-time staff, including Henry’s sister who quit her job to join the team, the start-and-stop business model became unsustainable. They needed systematic operations that could support consistent growth without constant crisis management.

Henry had learned from previous business failures that systematic approaches were essential for sustainable growth. When a colleague introduced him to SYSTEMology, he immediately recognized its potential for solving their operational challenges.

After Henry documented their first systems, he appointed an internal Systems Champion who keeps everyone accountable to systematic procedures while continuously recording and re-evaluating essential processes. This systematic approach enabled them to stay ahead of growth rather than frantically trying to catch up.

The transformation was remarkable. Bruce and Henry gained time and mental space to focus on vision and strategic initiatives rather than firefighting operational problems. Henry could dedicate his marketing expertise to creative, expansive projects instead of crisis management.

The key lesson: systematic operations transform growth from a crisis-inducing challenge into a manageable opportunity. When systems handle routine operations reliably, leadership can focus on strategic initiatives that drive continued success.

Case Study 2: Ecosystem Solutions Systematic Success

Gary McMahon’s journey with Ecosystem Solutions highlights how systemization can eliminate Murphy’s Law from both business operations and personal life.

The turning point came with the Critical Client Flow exercise, which Gary describes as his “game changer.” By mapping the business, he and his team identified operational bottlenecks and built cohesive processes to eliminate recurring problems. The results were dramatic: profitability increased by approximately 80%.

Equally transformative was the impact on Gary’s personal life. He took his first three-week family vacation in his entire career, saying: “It’s like I’ve lost fifty kilos! And I’ve got a life. It’s bizarre.” Today, Gary can step away for training or family time, confident his team will manage everything in his absence.

When asked what a systematized business means to him, Gary’s answer was simple: “Peace of mind.” With well-documented procedures, trained staff, and reliable quality controls in place, operations no longer depend on his constant presence.

Gary’s experience demonstrates how systems transform businesses from owner-dependent to self-sustaining. With predictable processes in place, Murphy’s Law loses its grip, and business owners gain both measurable results and lasting freedom.

The Systematic Approach to Murphy-Proofing

Step 1: Identify Your Murphy Hotspots

Begin Murphy-proofing efforts by conducting systematic analysis of where operational failures typically occur within your business. This audit reveals patterns that appear random but actually follow predictable systematic weaknesses.

Create a comprehensive list of recurring problems over the past 12 months. Include customer complaints, employee errors, equipment failures, deadline misses, quality issues, and any incidents requiring management intervention. Don’t limit analysis to major crises; include minor annoyances that happen repeatedly.

Map these problems against your Critical Client Flow to identify where Murphy typically strikes during customer interactions. Pay particular attention to handoff points between departments, communication touchpoints, and quality control moments.

Analyze the frequency and cost of each problem type. Which issues happen most often? Which create the highest financial impact? Which generate the most customer dissatisfaction? Which require the most management attention? This prioritization guides systematic intervention efforts.

Look for patterns that reveal systematic causes. Do training gaps contribute to human errors? Do unclear procedures create inconsistent execution? Do inadequate quality controls allow problems to reach customers? Do poor communication systems create coordination failures?

Document your findings in a Murphy Hotspot Analysis that prioritizes improvement opportunities based on frequency, impact, and systematic improvement potential. This analysis becomes the foundation for targeted Murphy-proofing initiatives.

Step 2: Design Prevention-Focused Systems

Transform reactive problem-solving approaches into proactive problem-prevention systems that eliminate Murphy’s opportunities for operational disruption. Prevention-focused design anticipates potential failures while building safeguards that maintain operational excellence.

For each identified hotspot, design systematic approaches that address root causes rather than treating symptoms. If training gaps contribute to errors, create comprehensive training systems with verification mechanisms. If unclear procedures cause inconsistency, develop detailed documentation with visual aids.

Build quality controls and checkpoints into every critical process. These systematic safeguards catch potential problems before they impact customers or require management intervention. Inspection procedures, approval workflows, and verification steps create multiple opportunities for error prevention.

Establish monitoring and early warning systems that provide visibility into operational performance before problems become crises. Performance dashboards, exception reports, and trend analysis help identify emerging issues while they’re still manageable.

Document contingency and recovery procedures for situations when prevention efforts don’t completely eliminate problems. These systematic responses minimize impact while enabling rapid recovery that maintains customer satisfaction and operational continuity.

Design systems with error-proofing principles that make mistakes difficult or impossible. Use checklists, automation, approval workflows, and verification procedures that systematically prevent common errors from occurring.

Step 3: Implement Error-Resistant Processes

Transform prevention-focused designs into operational reality through systematic implementation that builds organizational capabilities for Murphy-proof operations. Implementation success depends on thorough training, clear accountability, and consistent execution.

Create detailed checklists for all critical processes that include every essential step, specify completion criteria, and require verification signatures. These tools prevent oversights while providing clear guidance for consistent execution regardless of individual skill levels.

Establish foolproof procedures that eliminate common sources of confusion or error. Use standardized templates, automated workflows, approval requirements, and verification steps that systematically guide proper execution.

Train teams thoroughly in systematic problem prevention rather than just problem response. Help them understand why each step matters, how their work affects others, and what systematic thinking means for operational excellence.

Create feedback loops that capture learning from operational experiences while continuously improving systematic approaches. Regular team meetings, improvement suggestions, and process reviews ensure systems evolve with business needs.

Step 4: Monitor and Continuously Improve

Systematic Murphy-proofing requires ongoing attention to performance measurement, trend analysis, and continuous improvement that keeps prevention systems effective as business conditions change.

Track failure rates and system effectiveness using key performance indicators that reveal whether prevention efforts actually reduce Murphy’s impact. Monitor error frequencies, customer satisfaction scores, employee productivity measures, and management intervention requirements.

Establish regular review processes that examine near-misses and prevented problems, not just failures that occurred despite systematic efforts. Understanding what prevention systems catch successfully helps improve their effectiveness while building confidence in systematic approaches.

Create continuous refinement mechanisms that incorporate learning from operational experiences into improved systematic approaches. Monthly improvement meetings, quarterly system reviews, and annual strategic assessments ensure prevention systems evolve with business needs.

Celebrate systematic improvements and prevention successes to reinforce cultural commitment to Murphy-proofing efforts. Recognition programs, success story sharing, and improvement rewards create positive reinforcement for systematic thinking throughout the organization.

Measure and communicate the return on investment from Murphy-proofing initiatives. Document cost savings from prevented problems, productivity improvements from streamlined operations, and customer satisfaction enhancements from consistent service delivery.

Advanced Murphy-Proofing Strategies

Technology and Automation Safeguards

Modern technology provides powerful tools for Murphy-proofing business operations through automation, monitoring, and systematic documentation that reduces human error while improving operational consistency.

systemHUB creates central repositories for systematic documentation that make procedures easily accessible while maintaining version control and update capabilities. This systematic approach prevents the scattered documentation that contributes to operational inconsistencies and Murphy incidents.

Automated monitoring systems provide real-time visibility into operational performance while generating alerts when metrics exceed predetermined thresholds. These systematic safeguards enable proactive intervention before problems become crises.

Artificial intelligence can enhance many systematic processes by identifying patterns that humans might miss, predicting potential failures before they occur, and automating routine tasks that are prone to human error.

Digital checklists and compliance tracking systems ensure that critical procedures are followed consistently while providing visibility into systematic compliance across the organization. These tools make it easier to maintain high standards while reducing the cognitive load on team members.

Predictive maintenance systems analyze equipment performance data to anticipate failures before they occur, enabling proactive maintenance that prevents disruptions. This systematic approach transforms equipment reliability from reactive repairs to proactive prevention.

However, remember the principle of “think like Google”: perfect manual processes before automating them. Technology should enhance systematic operations, not replace systematic thinking.

Cultural Transformation

Building Murphy-proof operations requires cultural transformation that makes systematic thinking and prevention-focused approaches the natural way of doing business rather than an additional burden.

Help teams understand that systematic approaches ultimately make their work easier and more rewarding by eliminating recurring frustrations and enabling them to focus on higher-value activities rather than firefighting operational problems.

“Help teams understand that systematic approaches ultimately make their work easier and more rewarding by eliminating recurring frustrations.”

Train team members to think systematically about their work, looking for patterns and improvement opportunities rather than just completing assigned tasks. This mindset shift transforms individual contributors into systematic thinkers who contribute to organizational Murphy-proofing efforts.

Reward proactive problem prevention rather than just heroic problem-solving. Recognition programs should celebrate team members who identify and eliminate potential problems before they occur, not just those who solve crises after they happen.

Create systematic accountability that makes prevention-focused behaviors visible and valued throughout the organization. Performance reviews, team meetings, and improvement initiatives should emphasize systematic thinking and continuous improvement.

Establish systematic communication that keeps everyone informed about improvement initiatives, prevention successes, and learning opportunities. Regular updates about Murphy-proofing efforts help build organizational commitment while celebrating progress toward operational excellence.

Risk Management Integration

Advanced Murphy-proofing integrates systematic operations with comprehensive risk management that anticipates potential disruptions while building organizational resilience for unexpected challenges.

Connect systematic operations to risk prevention by identifying vulnerabilities within your Critical Client Flow and developing specific mitigation strategies for each potential failure point. This systematic approach transforms abstract risk management into concrete operational improvements.

Build resilience into business processes through redundancy, backup procedures, and alternative approaches that maintain operations when primary systems face disruption. Multiple supplier relationships, cross-trained team members, and distributed operational capabilities reduce dependency on single points of failure.

Develop crisis management and business continuity plans that provide systematic responses to various disruption scenarios. These procedures should specify communication protocols, alternative operating procedures, and recovery strategies that minimize impact while maintaining customer service.

Establish stakeholder communication systems that provide clear, timely, and accurate information during challenging situations. Systematic communication prevents confusion while maintaining confidence in your organization’s ability to handle difficulties professionally.

Create learning mechanisms that capture knowledge from prevention successes and occasional failures to continuously improve risk management capabilities. Post-incident reviews, prevention audits, and systematic improvement processes ensure organizational learning from all operational experiences.

The ROI of Murphy-Proof Operations

Systematic Murphy-proofing delivers quantifiable returns through multiple financial and operational benefits that compound over time as prevention systems mature and interact effectively throughout your organization.

Direct cost savings emerge from prevented problems including eliminated rework expenses, reduced error correction costs, decreased customer service burdens, and minimized crisis management overhead. Organizations typically see 15-25% efficiency improvements within the first year of systematic Murphy-proofing implementation.

Productivity improvements result from teams focusing on value-creating activities rather than firefighting operational problems. When systematic prevention eliminates recurring crises, human resources can be redirected toward strategic initiatives that drive business growth and competitive advantage.

Customer satisfaction and loyalty benefits develop as systematic operations deliver consistent, reliable experiences that build trust and confidence. Prevention-focused systems eliminate the service disruptions and quality variations that drive customers to competitors.

Employee morale and retention improvements occur when team members work in systematic environments that reduce stress, eliminate confusion, and enable professional success. Systematic operations create workplace conditions that attract and retain high-quality talent.

Business valuation enhancement results from systematic operations that demonstrate operational maturity and predictable performance to potential investors or acquirers. Companies with documented, systematic operations command higher multiples because buyers can see sustainable competitive advantages.

“Companies with documented, systematic operations command higher multiples because buyers can see sustainable competitive advantages.”

Risk reduction benefits include decreased liability exposure, improved regulatory compliance, enhanced business continuity, and reduced dependency on key individuals. Systematic operations create organizational resilience that protects against various forms of business disruption.

The investment required for Murphy-proofing typically pays for itself within 6-12 months through prevented problems and operational improvements, with continuing benefits accumulating as systematic capabilities mature and expand throughout the organization.

Common Challenges in Murphy-Proofing Your Business

Every organization implementing systematic Murphy-proofing encounters predictable obstacles that can be addressed through understanding and preparation rather than allowing them to derail improvement efforts.

The “it won’t happen again” mentality represents the most common challenge. After solving immediate problems, teams often assume that heroic efforts have permanently eliminated the underlying causes. This thinking prevents investment in systematic prevention approaches that would actually prevent recurrence.

Balancing systematic prevention with operational flexibility creates another frequent challenge. Teams sometimes fear that systematic approaches will reduce their ability to respond creatively to unique situations or changing business conditions.

Resolve this concern by designing systems that provide frameworks for consistent quality while allowing appropriate flexibility for special circumstances. Systematic approaches should establish minimum standards while enabling innovation within proven frameworks.

Resource allocation for proactive systems often meets resistance because prevention efforts require investment before problems occur. Leadership may question spending money to prevent problems that might not happen rather than addressing current pressing issues.

Counter this resistance by quantifying the cost of recurring problems and demonstrating the return on investment from prevention efforts. Historical problem costs usually far exceed systematic prevention investments when properly calculated.

Maintaining vigilance when systems are working well can become challenging because success makes systematic efforts seem less necessary. Teams may gradually relax their commitment to systematic approaches when they don’t see immediate problems.

Prevent this complacency by regularly reviewing prevention successes and near-misses that systematic approaches caught before they became problems. Celebrate systematic victories while maintaining awareness of what could happen without continued vigilance.

Your Murphy-Proofing Action Plan

Begin your systematic Murphy-proofing journey with a comprehensive assessment that reveals where operational failures typically occur while identifying the highest-impact improvement opportunities for your specific business situation.

Week 1-2: Murphy Hotspot Analysis Document all recurring problems over the past 12 months, including frequency, cost, and impact on customer satisfaction. Map these problems against your Critical Client Flow to identify vulnerable points in your core operations.

Week 3-4: Critical Client Flow Development Create your Critical Client Flow by mapping one client type’s complete experience with one primary product or service. Test this with someone outside your business to ensure clarity and identify improvement opportunities.

Week 5-6: Minimum Viable Systems Identification Identify 7-10 critical systems per department that, when properly documented and implemented, would prevent 80% of recurring problems. Prioritize based on customer impact, revenue generation, and operational efficiency.

Week 7-8: System Design and Documentation Begin documenting your highest-priority systems using prevention-focused approaches that include quality controls, error-proofing techniques, and monitoring mechanisms.

Week 9-12: Implementation and Training Roll out systematic approaches with comprehensive training that helps team members understand why systematic thinking matters and how they contribute to Murphy-proof operations.

Month 4-6: Monitoring and Refinement Establish measurement systems that track prevention effectiveness while continuously improving systematic approaches based on operational experience and team feedback.

Month 7-12: Expansion and Cultural Integration Expand systematic approaches to additional processes while building organizational culture that makes prevention-focused thinking the natural way of doing business.

Throughout this process, maintain focus on the compound benefits of systematic approaches. Small improvements made consistently create breakthrough results over time as prevention systems interact and reinforce each other’s effectiveness.

Frequently Asked Questions About Murphy-Proofing Business Operations

From Murphy’s Victim to Master of Your Destiny

Murphy’s Law will always exist in some form because we live in an imperfect world where unexpected events occasionally disrupt even the best-planned operations. However, you don’t have to remain helpless victim to Murphy’s apparent conspiracy against your success.

The systematic approach to Murphy-proofing transforms your business from reactive crisis management to proactive problem prevention. As Benjamin Franklin wisely noted, “An ounce of prevention is worth a pound of cure.” Instead of constantly fighting fires, you build organizational capabilities that prevent most fires from starting while maintaining excellent response capabilities for the few that do occur.

Gary McMahon’s transformation from 100+ hour work weeks to peaceful family vacations demonstrates what becomes possible when systematic thinking replaces Murphy thinking. Bruce and Henry’s evolution from operational chaos to scalable growth shows how systematic approaches enable sustainable success rather than exhausting crisis management.

The choice is yours: continue accepting operational chaos as “normal” while remaining Murphy’s victim, or invest in systematic approaches that put you in control of your business destiny. As the wisdom goes, “YOU are in command of your fate. YOU determine how many mistakes, errors, or problems are acceptable.”

Replace Murphy’s Law with the laws of systematic thinking: effective systems and processes are essential building blocks of successful businesses; systematic thinking represents the master skill of entrepreneurship; constant improvement of business processes drives customer loyalty, profitability, and growth; and the true value of a business lies in the maturity of its systematic operations.

“The choice is yours: continue accepting operational chaos as “normal” while remaining Murphy’s victim, or invest in systematic approaches that put you in control of your business destiny.”

The SYSTEMology movement provides proven frameworks, practical tools, and supportive community for business owners ready to defeat Murphy’s Law through systematic excellence. Your journey from chaos to systematic control begins with a single decision: will you continue reacting to Murphy’s mischief, or will you build the systematic capabilities that put you in command of your business destiny?

Murphy’s Law doesn’t have to rule your business. Systematic thinking can.