Every product, service, or transaction-based business runs two operations simultaneously. There’s the Main Factory, where you deliver products and services to customers. Then there’s the Fix-it Factory, where you handle everything that goes wrong.

Rework. Returns. Refunds. Customer complaints. Rush orders. Quality control failures. Communication breakdowns. Each mistake demands resources to fix. Each delay costs time and money. Each frustrated customer requires attention that could serve new ones.

Jay Arthur, author of Small Business Guide to Six Sigma, coined this concept. And here’s why it matters: experts estimate the average small business wastes at least 3% of revenue. That might sound manageable until you do the math.

For a company generating one million dollars in sales, 3% waste equals $30,000. But waste doesn’t come from revenue. It comes straight from profit. If your net profit margin is 8% ($80,000), that waste reduces actual profit to $50,000. You just lost 37.5% of expected earnings to preventable problems.

Want to recover that loss? You’d need nearly $400,000 in additional sales. That’s the brutal reality of waste economics. At typical business margins, every $1 saved in costs equals $10-20 in equivalent new sales required to generate the same bottom-line impact.

What’s in this article:

Why Small Business Waste Hits Harder

Beyond Financial Loss: The Full Cost of Business Waste

Stage 1: Define Your Critical Client Flow

Stage 2: Assign Responsibility for Systems Development

Stage 3: Extract the Knowledge of Excellence

Stage 4: Organise Your Systems in a Central Location

Stage 5: Integrate Systems Into Team Training

Stage 6: Scale Your Business with Systems Thinking

Stage 7: Optimise Systems for Continuous Improvement

What Excellence Looks Like: The Walmart Standard

Real Results from the SYSTEMology Framework

Your 30-Day Waste Elimination Action Plan

What to Expect: The Transformation Timeline

Where to Start Right Now

Frequently Asked Questions

Why Small Business Waste Hits Harder

Large corporations absorb waste through scale and deep pockets. Small businesses can’t.

Your profit margins are thinner. Your resources are limited. Your personal reputation connects to every transaction. When things go wrong, you feel it immediately in your bank account and your stress levels.

Consumer demand for customisation increases complexity. Staff turnover reduces institutional knowledge. Market pressure demands faster delivery. No wonder mistakes happen.

But here’s the thing: most small business waste isn’t random bad luck. It’s a systematic failure.

The Hidden Patterns

Order processing errors. Incomplete project specifications. Miscommunication between team members. Quality issues discovered after delivery. Rush jobs created by poor planning.

These patterns repeat because the systems that prevent them either don’t exist or aren’t followed consistently. The knowledge of how to avoid mistakes lives in the heads of your best performers. When they’re absent or leave, that knowledge disappears.

Money isn’t the only casualty of your Fix-it Factory.

Gary McMahon at Ecosystem Solutions experienced this firsthand. Working 100-110 hours per week, he was constantly firefighting. His health suffered. His family relationships strained. His business struggled despite growing demand.

“I was the quintessential bottleneck,” Gary explained. “Every tool and all the training I could find didn’t help. I knew it had something to do with systems, but I didn’t know what.”

Beyond Financial Loss: The Full Cost of Business Waste

Money isn’t the only casualty of your Fix-it Factory.

Customer defections multiply. According to PwC’s global research, 32% of customers stop doing business with a brand they loved after just one bad experience. In the U.S. market, 59% walk away after several bad experiences. Zendesk’s 2023 Customer Experience Trends Report shows this trend intensifying, with more than 60% of customers now defecting after a single poor interaction.

The financial impact compounds quickly. Bain & Company research published in Harvard Business Review found that increasing customer retention rates by just 5% increases profits by 25% to 95%, depending on the industry.

Team morale suffers. Constantly fixing mistakes burns out your best people. They start feeling like hamsters on a wheel, working harder but never getting ahead. The ones who care most often leave first because they’re frustrated by the chaos.

Your time disappears. Every hour spent in the Fix-it Factory is an hour not spent growing the business, serving clients, or having a life outside work. The owner becomes trapped as the chief problem-solver, unable to step away without everything falling apart.

The SYSTEMology Framework: 7 Stages to Eliminate Business Waste

Shutting down your Fix-it Factory requires a systematic approach. SYSTEMology is a seven-stage framework designed to identify and create the critical systems within your business, get your team following them, and continue to optimise them over time.

Waste elimination isn’t a one-time project. It’s an ongoing cultural commitment.

Here’s how the framework addresses waste at its source.

Stage 1: Define Your Critical Client Flow

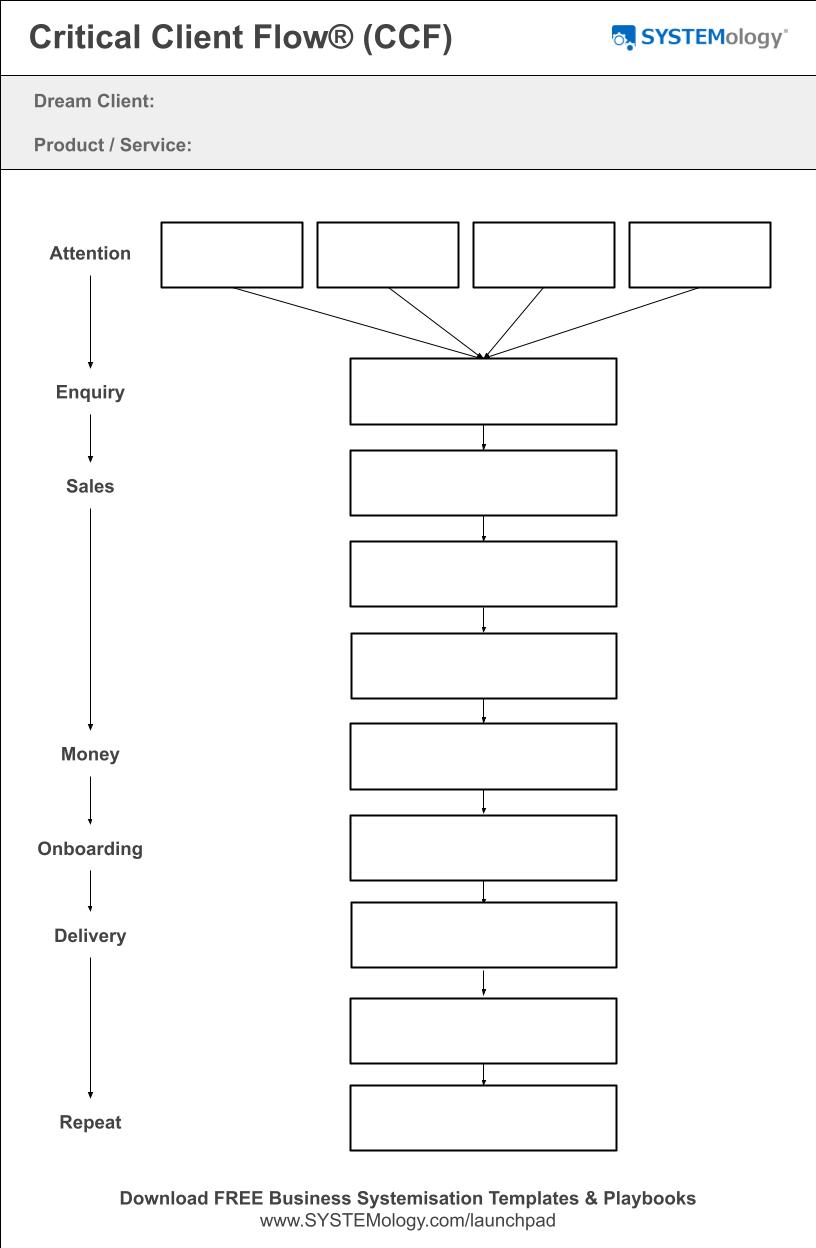

The first stage in SYSTEMology is to reduce the overwhelm. Your Critical Client Flow (CCF) maps every step from customer inquiry to final delivery. This is where waste typically generates.

You don’t need hundreds of systems to systemise your business. You simply need to pick one target audience, one central product or service, and define the Critical Client Flow.

Most business owners think they know their process. They don’t. When you document the actual journey customers take through your business, gaps become obvious.

You’ll see the handoffs where information gets lost, the approval bottlenecks that create delays, and the decision points where mistakes multiply.

Start with one target client and one primary product. Don’t overthink this. Map what you’re currently doing, not what you wish you were doing.

The goal is to identify 10-15 critical systems as your starting point.

Stage 2: Assign Responsibility for Systems Development

The second stage in SYSTEMology recognises that the knowledge of how to do a task to a great standard already exists within your team.

Here’s an uncomfortable truth: business owners are typically the worst people to document waste elimination systems. You’re too close to the problems and too busy firefighting to see systematic solutions.

Your best team members already know how to avoid common mistakes. They’ve developed workarounds, shortcuts, and quality checks that live only in their heads. This knowledge walks out the door every evening.

A Systems Champion role bridges this gap. This person takes ownership of extracting, documenting, and systematising the tribal knowledge that prevents problems before they occur. Look for someone detail-oriented who gets satisfaction from seeing things run smoothly.

At PorterVac, a specialist gutter cleaning and roof maintenance company in Melbourne, Kane was a curious twenty-year-old who worked in their head office. Over several months, he helped connect the right team members, attended implementation sessions, and even grabbed a camera to capture processes in the field.

The results proved that you don’t need special training to be a Systems Champion. The right person just “gets” this stuff.

Stage 3: Extract the Knowledge of Excellence

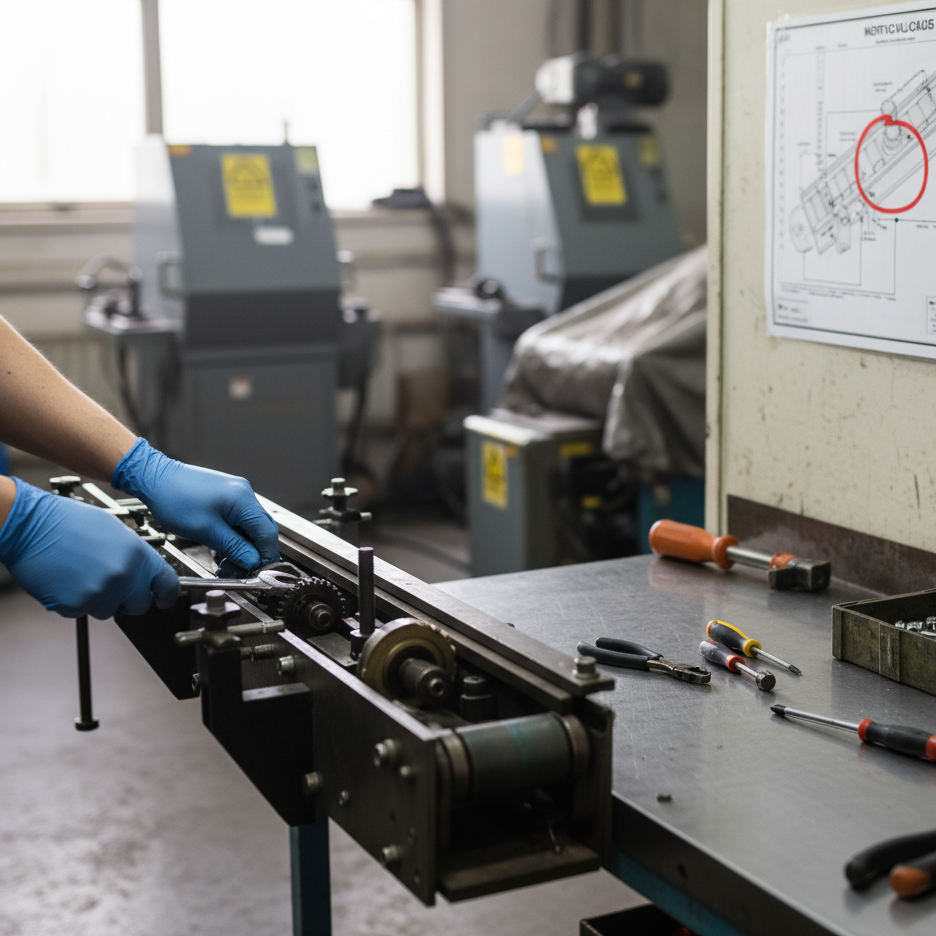

The best way to build waste-prevention systems is to capture how your top performers already avoid mistakes. They’ve solved problems through trial and error. Your job is to document their methods so others can replicate them.

Use whatever technology works. Video recordings with smartphones. Screen capture software. Simple written checklists. The goal is capturing how excellence happens so it can be repeated consistently.

Get “version one” done quickly. Fighting strong resistance head-on is rarely the best way forward. Have someone else create the initial documentation, then get the knowledgeable worker to review it. This approach produces better results than asking experts to write their own systems from scratch.

Stage 4: Organise Your Systems in a Central Location

Documentation without organisation creates new waste. Systems scattered across email, shared drives, and sticky notes don’t prevent problems.

Centralised system storage makes prevention easier than fixing. When the right process is one click away, people follow it. When they have to hunt for information, they improvise. And improvisation is where errors breed.

Your systems hub should be accessible from any device, organised by role or department, and updated whenever processes change. This becomes the single source of truth for how work gets done.

Shutting down your Fix-it Factory requires a systematic approach.

For teams looking to make their systems easy to find and follow, the systemHUB SOP software is one option to consider.

Stage 5: Integrate Systems Into Team Training

Culture change requires more than documentation. It requires making systematic excellence the path of least resistance.

Southwest Airlines understood this in the 1970s. While other airlines hired for technical expertise and years of experience, co-founder Herb Kelleher took a different approach: hire for attitude, train for skill.

Southwest replaced traditional interviews with group sessions where recruiters watched how candidates interacted and solved problems together.

They weren’t looking for the most qualified aviation professionals. They were looking for people who naturally brought enthusiasm, flexibility, and warmth to their work.

The result? While competitors battled high turnover and customer complaints, Southwest built one of the most successful cultures in airline history.

They didn’t achieve this by changing people. They achieved it by selecting people who were already a natural fit.

You might not be able to replace your entire team, but you can apply the same principle. Identify who embraces error prevention and who needs additional support. The Conscious Competence Ladder explains why some people adapt faster:

- Unconscious Incompetence: Don’t know better methods exist

- Conscious Incompetence: Aware of gaps, motivated to improve

- Conscious Competence: Following systems with conscious effort

- Unconscious Competence: Excellence becomes automatic

Meet people where they are, not where you wish they were.

Stage 6: Scale Your Business with Systems Thinking

Once core waste elimination systems prove effective, expand systematically. Don’t try to fix everything simultaneously.

The goal is removing yourself as the bottleneck. Identify where your personal involvement creates delays, then systematically hand off routine decisions to documented processes and trained team members.

This is where the compounding effect begins. Multiple systems working together create reliability that exceeds what any individual could maintain. New employees onboard faster. Quality becomes consistent. And you gain the freedom to step away without everything falling apart.

Stage 7: Optimise Systems for Continuous Improvement

Waste elimination isn’t a one-time project. It’s an ongoing cultural commitment.

Regular system audits identify new waste sources as your business evolves. Customer feedback reveals pain points you might miss internally. Team suggestions often highlight the most practical improvements.

The process is simple: identify a problem, add it to the problems list, discuss and deploy a solution, monitor results, and if successful, document it as part of your new process. If the solution doesn’t deliver expected results, repeat the cycle.

The goal isn’t perfection. It’s progress that compounds over time.

What Excellence Looks Like: The Walmart Standard

Walmart operates distribution centres spanning twenty-four football fields with nineteen miles of conveyor belts. Multiple trucks load simultaneously at dozens of docks.

Here’s what separates them: they measure efficiency by the space between boxes on conveyor belts.

If boxes touch, maximum loading occurs. Space between boxes represents waste, increasing per-unit costs. This obsessive attention to detail drives their competitive advantage.

Small businesses can apply this thinking without corporate complexity. Look for the “space between boxes” in your operations. Those gaps represent profit opportunities waiting to be captured.

Real Results from the SYSTEMology Framework

Ecosystem Solutions: From Chaos to Clockwork

Gary McMahon founded Ecosystem Solutions in 2005. The ecological consulting business helps clients from governments and corporations to families. Demand grew quickly, but success came at a devastating personal cost.

Working 100-110 hours weekly, Gary became his business’s biggest bottleneck. Every decision flowed through him. Every problem landed on his desk.

“This is my only hope,” he said when discovering SYSTEMology.

Most business owners think they know their process. They don’t.

The transformation began with mapping his Critical Client Flow. Suddenly, bottlenecks became visible. Waste patterns emerged. Most importantly, solutions became clear.

By systematically removing himself from routine decisions, Gary achieved an 80% profitability increase. But his greatest win wasn’t financial.

“It’s like I’ve lost fifty kilos! And I’ve got a life. It’s bizarre,” Gary said.

Today, Gary can leave for a training or family day any time and trust that his team handles everything while he’s away. His first three-week holiday in his entire working life? That happened too.

When asked what it means to have a systemised business, Gary’s answer was simple: “Peace of mind.”

Vocal Manoeuvres Academy: Simplicity That Works

Alison Rogers initially resisted systematic approaches. “It’s too simple,” she insisted. “It’s just collecting money.”

That resistance cost her business efficiency and profit. She described her previous state as “a constant state of heightened anxiety, always on tools, always working.”

Once she embraced the SYSTEMology framework through the Critical Client Flow process, everything changed. “I was really surprised at the amount of remuneration I was receiving with a broken CCF,” she shared. Financial profitability improved within six months.

Now her team speaks in systems language. “We all talk CCF and DRTC and SAS and MBS now. I’m able to replicate successful processes for every service we offer. Fast, functional, and fun.”

Your 30-Day Waste Elimination Action Plan

Week 1: The Waste Audit

Identify your top three waste sources. Look for repeated customer complaints, internal rework patterns, process delays and bottlenecks, and quality control failures.

Calculate the financial impact. Use the 3% baseline as your starting point, but dig deeper. Track how much time your team spends fixing problems versus preventing them. Document current Fix-it Factory activities. You might be shocked by what you discover.

Weeks 2-3: System Implementation

Choose your highest-impact waste source. Don’t try to fix everything simultaneously.

Create prevention documentation that captures how your best performers avoid these problems. Use video recording for complex processes, simple checklists for routine tasks. Get team input during this phase. The people doing the work often have the best insights about what creates problems and what prevents them.

Week 4: Monitor and Expand

Launch your waste elimination system with clear communication about why it matters. Track reduction in Fix-it Factory activities.

Measure both leading indicators (prevention activities) and lagging indicators (problem frequency, cost savings, customer satisfaction). Gather feedback actively. What’s working? What’s creating new friction?

Plan your next waste elimination target based on results and team confidence.

Your business is capable of running more smoothly than it currently does. Sometimes it just needs systems that make excellence easier than mediocrity.

What to Expect: The Transformation Timeline

Months 1-3: Foundation Building. Expect initial resistance from team members comfortable with current chaos. Some people have adapted to inefficiency and built workarounds that feel familiar. Early wins often appear in reduced daily firefighting. Fewer emergency meetings. Less reactive problem-solving. Financial impact starts small but compounds quickly.

Months 4-12: Cultural Shift. This is where the magic happens. Multiple waste elimination systems start working together. Your team develops prevention thinking as their default approach. New employees onboard faster because training is systematised. Customer satisfaction improves because quality becomes consistent.

Businesses implementing systematic process improvements typically see 25-30% productivity improvement within the first three years. The key is sustained commitment, not quick fixes.

As one business owner described it: “Everything will come together. Certain elements of your job will either take a fraction of the time they used to take, or you will delegate entirely.”

Frequently Asked Questions

Where to Start Right Now

Gary didn’t fix everything at once. He started by mapping his CCF and tackling the waste that hurt most.That’s all you need to do.

Find your costliest waste source. Not the most complex problem or the one that seems most impressive to solve. Find the one creating daily frustration and quietly draining profit. Start there.

And don’t overthink it. A simple system implemented today beats a perfect system still in planning next quarter. You can refine as you go.

The goal isn’t to eliminate every problem forever. That’s not realistic, and chasing it will burn you out. The goal is to build the capability to prevent problems before they happen. Create one prevention system, watch what changes, and then expand from there.

Your Fix-it Factory doesn’t have to be permanent. With the right approach, you can shut it down for good.

Eager to get started? Sign up to systemHUB now for $1.